Technologies

Rotary, scribing

Ideal for

Trophy engraving

Cylinder engraving

Sign making

Metal engraving and milling

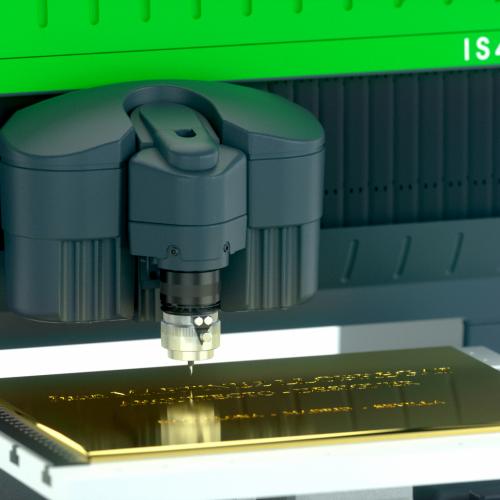

IS400 – IS400 Volume, the engraving machine for flat and cylinder engraving

Rotary, diamond engraving

305 x 210 mm

Plastics, metals and organic materials (glass, wood).

- Precise and steady engraving on all materials

With key features such as point and shoot, high-frequency spindle, and our onboard software Gravostyle™, the IS400 CNC engraver simplifies your workflow and ensures a consistent engraving on any surfaces, flat or non-flat without permanent supervision of the operator.

- Durability

These engraving machines are a success thanks to their outstanding robustness, whichever the quantity of work they intake. With an adjustable rotation speed, IS400 and IS400 Volume rotary engravers are designed to meet the demanding marking and machining needs in the industry.

- Plastic and metal engraving machine

IS400 can mark on all materials, from the softest plastic such as PEHD to the very hardest metal like steel. Excellent results in your applications: metal milling to create front panels, surface engraving for light signage... IS400 also is a powerful metal plaque engraving machine that provides deep markings.

Technical Specifications

Solid cast aluminium frame

Heavy-duty spring-loaded

Gripper or high-frequency spindle with collet options

Ball-bearing lead screws.

LCD control panel

USB data transfer cable

Point & Shoot function, with laser pointer

Auto Z-ref function

Software included Gravostyle™ Discovery

Various options and accessories are available with your IS400 engraving machine

- Ranges of engraving and machining tools: Diamond, Twincut, Onecut, Percut

- Tool lubrication system

- Range of regulating and suction noses

- Chip collectors

- Pen attachment system

- Cylinder attachment for cylinder engraving

- Aluminium clamping table

- Braille ADA kit for a complete sign solution

- Flange table

IS400: diameter 120 mm

IS400 Volume: diameter 350 mm and tilting to 45 mm

General

Marking Capacity

Marking area max

305 mm (12.008 in) x 210 mm (8.268 in)

Spindle power

90 W

Optional spindle: 150 W

Max object height

IS400: 105 mm (4.134 in)

IS400 Volume: 400 mm (15.748 in)

With more than 10,000 units sold, the IS400 metal engraving machine is a stable, safe choice, versatile, CNC engraver.

Since the nineties, most of the IS400s' sold are still running in all types of industries, which proves its reliability and durability.

The IS400 can also be split from its base so it can be attached to a customised support.

You are free to define your own engraving axis, tilt angle, automation to work at competitive cost on rail or aviation components, wind turbine blades, etc.

Unique to the market, the IS400 Volume opens new possibilities with the biggest stroke available in the industry.

It is equipped with a motorised fixing system that allows the passage from flat engraving to cylinder engraving (optional cylinder turner) without adjusting.

Mainly used in any industry with bulky parts such as funeral urns, aeronautical landing gear, and automotive engine blocks, it also is the ideal trophy engraving machine.

The IS400 metal plaque engraving machine is designed to optimise your workflow:

- automatic plate feeder for mass production,

- ability to switch from cylinder engraving to flat engraving in less than 30 seconds,

- large choice of engraving tools (Diamond, Twincut, Onecut, Percut),

- range of jigs for all shapes of objects

- ability to use your own tools

This engraving machine can engrave +20 materials

| ROTARY | DIAMOND DRAGGING | |

|---|---|---|

| ORGANICS | ||

| Glass, crystal | ||

| Leather | ||

| Wood, varnished wood | ||

| PLASTICS | ||

| ABS | ||

| Foam | ||

| Laminates | ||

| PA | ||

| PC | ||

| PE, BET | ||

| PMMA, Acrylic | ||

| POM - PBT | ||

| PP | ||

| METAL | ||

| Aluminum | ||

| Anodized Aluminum | ||

| Brass | ||

| Coated metal | ||

| Copper | ||

| Gold, silver, nickel, platinum | ||

| Stainless steel | ||

| Steel | ||

| Carbide | ||

| Titanium | ||

Associated Products

A robust material specifically for mechanical engraving

Gravoply™ 1

Metallic appearance for a high-end finish

Metallex™

The advantages of aluminium combined with those of a phenolic base

Gravostral™

The versatile outdoor acrylic material

Gravoglas™ 2-plex™ Surface

The reverse outdoor acrylic material

Gravoglas™ 2-plex™ Subsurface

The aluminium range dedicated to engraving and cutting

Gravoxal™

The material in watchmaking-quality brass for outdoor use

Gravobrass™ Exterior

Gravolaque

Nitrolaque

Other content you might like

IS400: A Gravograph customer’s dream comes true

The unmatched compromise between power and compactness

Replacing the irreplaceable: this has been the Gravograph team challenge back in the 90’ when deciding to replace the VXM, one of our best-selling, yet aging, machine. Focus was set on offering a lightweight industrial machine for small to medium part identification, while keeping the outstanding reliability that made Gravograph machines a worldwide success: the IS400 was born!

As for the IS400 Volume, it was created to be the perfect engraving machine for Gravograph industrial customers: no more time wasted in switching from flat to cylindrical engraving mode, bulky item engraving capability and high productivity. The Gravograph team took the IS400 and added a motorized fixing system.

Today, the IS400 and IS400 Volume are widely used in various industries with bulky parts to engrave.