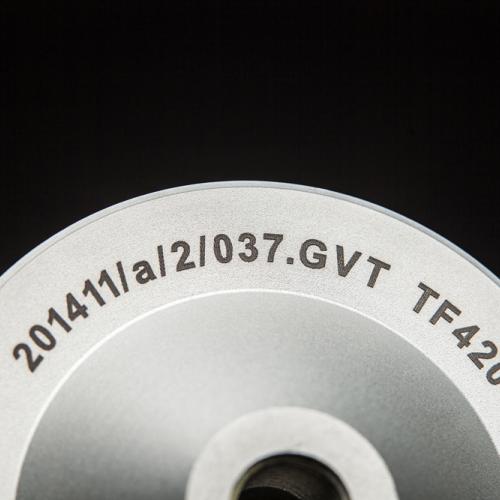

Marking mechanical parts is essential for identifying and inscribing informative data and codes on products, ensuring traceability throughout their life cycle. This step is a requirement for industrial companies to track their manufactured items effectively.

The need for industrial part marking in manufacturing is universal, applicable to both large industries producing components at high rates and smaller workshops with limited daily production.

Implementing a traceability system for mechanical parts is a significant challenge for companies and involves an investment. Gravotech offers turnkey identification machines with various technologies for marking parts, including small and medium series, at a controlled cost.

Our direct part marking systems

Laser markers are versatile and can be applied to all types of components, including plastic, metal, organic minerals, and others.

Our laser workstations are designed to efficiently mark components, whether in series or individually, without causing any disruption to your working environment. These stations are Class 1 certified, ensuring the highest level of laser security, and they are compatible with all our laser technologies.

For more demanding and high-speed production lines, our integrable laser range guarantees flawless identification of your parts.

Medium fully automated laser marking station.

LW2

Large fully automated laser workstation with Fiber, Hybrid or Green sources

LW3

Integrated laser system to mark and engrave on all metals.

FIBER laser

Integrated laser system for high quality marking on plastics and metals.

HYBRID laser

Integrated laser system for high quality and cold marking on plastics and precious metals.

GREEN laser

Create long-lasting and forgery-proof markings on metal or plastic workpieces with exceptional speed and precision.

The IMPACT range of dot peen marking stations can efficiently mark parts of different sizes and shapes. These identification machines will easily fit into your workspace.

If you have high-production rates, our integrable range is the ideal solution, as it can be easily incorporated into your existing production line.

Standalone dot peen marking station.

IMPACT

The fastest pneumatic dot peen marking machine.

XF510p

The most precise and consistent electromagnetic dot peen marking machine.

XF510M

Deep and permanent dot peen marking system.

XF530 p/m

Scribing machines offer unparalleled speed, quality, and reliability for industrial part marking, regardless of your production volume.

This system enables direct part marking on your components while significantly reducing noise levels. Its quiet operation meets the strictest noise control standards, making it the ideal industrial marker for steel marking, traceability marking, and production line applications.

Gravostyle™ and Lasertrace are two software solutions designed for marking and engraving a wide variety of materials. Gravostyle™ is a CAD/CAM software equipped with graphic and design features, while Lasertrace facilitates traceability and identification for all types of parts.

|

Want to learn more about direct part marking methods ? |

|---|

Select the right DPM machine depending on your application

Your direct part marking needs vary depending on your company size and activity.

As a small company with punctual DPM needs, you might prefer a cheaper identification machine such as the Impact.

Depending on the sector, part marking might be mandatory and must comply with relevant standards and regulations to ensure product conformity. You might then prefer a high-speed integrable marking machine.

We are able to implement a "total quality" system, that allows parts to be associated with each production machine they go through.

We have the right industrial part marking solution to match your materials, production speed and mechanical parts specific characteristics.

Your parts material is another criteria when choosing your part marking system.

Our marking machines are compatible with the following materials:

- Metallic materials: steel, stainless steel, aluminum, tin, titanium, carbides…

- Plastic materials: ABS, PA, PE, POM, PBT, PP…

- Organic materials: ceramic, rubber, cardboard, wood…

Note: each of our laser markers, dot peen and scribing machines are compatible with some materials only. Contact an expert to determine which technology is the most appropriate.

The shape of your parts to be marked will highly influence the marking system choice as well.

- Tubular metallic parts require a silent marking system to comply with noise regulation standards.

- Long and flat parts need an open-structure marking system.

- Circular or conic parts demand a marking machine equipped with a rotary device.

- Finally, multishaped parts require an auto-focus marking system.

Contact us and get your free feasability check

IDENTIFICATION

Trust our expertise, discover our dedication

You are a global industrial company looking for a trusted partner for your identification needs?

With a rich legacy of innovation and a deep understanding of industry requirements, Gravotech offers a wide range of solutions for Identification requirements.

Through a collaborative approach, Gravotech works closely with its clients to understand their unique needs and challenges, allowing them to develop solutions that deliver consistent and precise results.

With a global network of dedicated support professionals, Gravotech ensures that Key Accounts receive prompt assistance and ongoing technical support, thereby maximising uptime and minimising downtime.