Direct Part Marking (DPM) is the process used to mark information on the surface of industrial parts.

But what exactly is it? And what are the different direct part marking methods?

Here is everything you need to know!

What is direct part marking in the industry?

Direct part marking is a set of techniques used in the industrial sector to identify or inscribe data on your products : serial numbers, manufacturing dates, bar codes, Datamatrix codes, logos.

The objective? To guarantee the traceability of manufactured products throughout the supply chain and their life cycle.

|

Get our DPM methods |

|---|

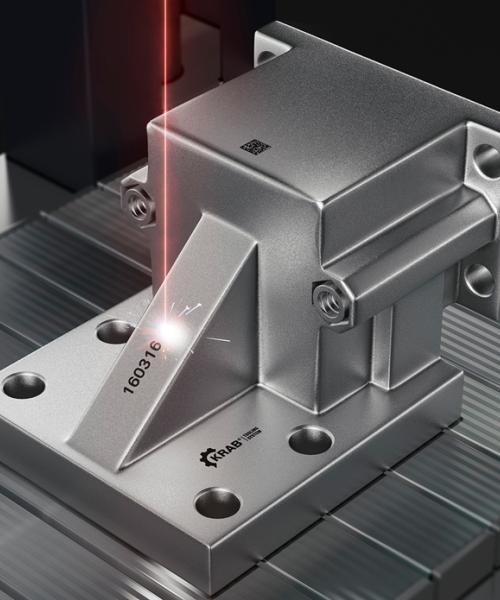

Laser marking

An industrial laser engraver uses a laser beam to interact with the material and create a permanent marking. This chemical reaction can produce different effects depending on the surface condition, the material of the part, the type of laser used and the marking parameters selected.

Compared to mechanical technologies (dot peen marking machines and scribing), laser marking is less deep.

There are several types of laser sources to mark different types of materials:

- Laser Fiber (metals)

- Laser Hybrid (metals and plastics),

- Laser Green (reflective and sensitive materials),

- Laser CO2 (organic materials: wood, rubber, paper, glass).

Laser technology offers many benefits for part identification:

- Silent: the noise generated by the interaction between the industrial laser engraver and the material is minimal, and the extractor, if equipped, emits a discreet blowing sound.

- High precision: it produces a delicate and precise marking perfectly adapted to small characters, logos and 2D codes of very small sizes. Ideal for the medical industry.

- Very high speed: this is the fastest direct part marking method compared to others.

- Different marking effects depending on the type of part, your needs and projects.

- No consumables required.

However, laser technology can have some limits for DPM:

- Price: initial investment is higher than a dot peen or scribing machine.

- Laser safety: a laser beam is powerful and can be dangerous to the operators. It is essential to install a suitable and approved safety system. Gravotech offers you protection boxes (LW2) or protection tunnels (Mini-inline) to upgrade your integrated laser from Class 4 (dangerous and your operators must be equipped with PPE)to a Class 1 industrial laser engraver (total protection).

- Set up: the laser is a very versatile and complex tool. Training is required to operate the machine and set its parameters. However, once the marking is configured, the industrial laser engraver can be triggered by any operator.

Dot peen marking

Dot peen marking machines use a mechanical engraving technique that deforms the material of a part into an indentation to mark it with very little breakage (no heat, no chips because the material is pushed back and therefore no change in weight).

The part identification is done thanks to a vibrating stylus whose tip strikes the surface of your part via a pneumatic or electromagnetic mechanism. This tip oscillates at a high frequency, between 1 to 300 times per second.

The stylus moves over a marking area of variable size, depending on the type of industrial engraver being used.

This technology was invented by our experts at Gravotech (Technifor) almost 40 years ago and is now used worldwide! Some of our dot peen marking machines have been running continuously on production lines for decades...

Pneumatic:

Pneumatic dot peen marking uses compressed air. Like a small jackhammer, the tip of the stylus strikes the workpiece and is brought back to its initial position by a spring. The oscillation frequency is very high, between 150 to 300 Hertz (150 to 300 impacts per second). This makes it a very fast direct marking method.

Electromagnetic:

Electromagnetic dot peen marking machines uses a powerful electromagnet that is electronically controlled. With each electrical impulse, the tip of the stylus is propelled violently toward the part to create a sharp, deep impact, then returns to its initial position thanks to a spring. The impact frequency can vary between 1 to 40 Hertz (1 to 40 strokes per second) depending on the desired effect.

Discover our dot peen machines

Dot peen marking is the most widely used technique for direct part marking (DPM):

- Permanent: high resolution marking easily readable by humans and highly resistant to wear and tear.

- Forgery-proof: very deep marking (up to 0.5 mm in steel).

- Marks but does not alter: this part marking method compresses the material without altering the properties of the part, so there is little risk of breakage or weight variation. These last advantages are crucial in the aeronautics and aerospace sectors.

- Versatile: this technology can be used on a wide variety of materials (metals, plastics) and parts of different shapes and sizes.

- Robust: our machines are designed to last for decades and operate in the most demanding environments.

- Economical: no consumables or environmentally harmful cleaning products.

Dot peen is the most common solution to mark industrial parts, but it also has some limits:

- Non-contrasting marking: mechanical engraving pushes the material and creates a relief marking without adding or changing color.

- Noise level: the stylus hits the parts to mark them so the noise level is higher than other part marking systems such as scribing machines or industrial laser engravers, especially on large metal and/or hollow parts.

- Pen replacement: the stylus and its tip can wear out more or less quickly depending on the materials, type of marking and frequency of use.

- Less delicate: fast and accurate, dot peen industrial engravers are not really delicate. If the priority is aesthetics, laser marking would be more appropriate.

Scribing marking

Scribing industrial engravers use a carbide or diamond tip to create a continuous, clean, and aesthetic marking. The tip glides over and scratches the part leaving a permanent, deep and clearly legible mark.

Scribing is a part identification solution dedicated to metal: it can be used on a wide variety of metal parts such as aluminum, brass, and copper, as well as hard materials such as steel and stainless steel.

Scribing part marking systems also offer another important advantage: by remaining in continuous contact with the parts, the part identification process is much quieter than dot peen, which strikes the parts. Scribing is therefore recommended for materials that resonate, such as sheet metal and hollow parts.

Scribing has many advantages for industrial direct part marking:

- Quieter: scribing has the advantage of being a low-noise identification solution because the tip glides over the material, unlike dot peen for example.

- Low compressed air consumption: compared to a dot peen marking machine.

- Precise and aesthetic: our scribing industrial engravers feature highest quality double-rail guidance and a ball-screw drive to ensure clean, high-quality marking on all parts.

- Readable: fast and easy OCR (Optical Character Recognition) scanning of 2D codes and markings.

- Metal expert: marking possible on all industrial parts, from soft to very hard metals.

Scribing has few disadvantages for DPM needs, but there are two to consider:

- Clamping: the part must be held firmly so that it can be marked correctly. In some cases, clamping the part is necessary for its manufacture (welding, stamping, etc.), which facilitates the subsequent marking procedure.

- Replacing the stylus: depending on the material, the type of marking and the frequency of use, the stylus and its tip may wear out more or less quickly.

Our direct part marking systems

Integrated laser system to mark and engrave on all metals.

FIBER laser

Integrated laser system for high quality marking on plastics and metals.

HYBRID laser

Integrated laser system for high quality and cold marking on plastics and precious metals.

GREEN laser

Integrated laser system to mark organic materials.

CO2 laser

Standalone dot peen marking station.

IMPACT

The most precise and consistent electromagnetic dot peen marking machine.

XF510M

The fastest pneumatic dot peen marking machine.

XF510p

Deep and permanent dot peen marking system.

XF530 p/m

Other direct part marking methods

Label marking on industrial parts

Label marking involves printing information on a label and then sticking it onto a part.

This identification solution is best suited to temporary marking or identifying parts that are not visible to the end customer, such as those inside a vehicle.

Historically used to identify plastic parts, this method is tending to disappear in favour of permanent marking techniques that are more compatible with today's safety, quality control and classification requirements.

The benefits of this type of marking for direct marking on parts:

- Simplicity: This process is easy to set up and use. It does not require expensive machinery.

- Legibility: Printed Datamatrix or bar codes are easy to read, thanks to contrasting black print on a white background.

- Economical: This type of machine and code readers are very affordable.

The limits of marking by label:

- Non permanent marking: its use is limited to identification in the production plant or when a part is protected during its period of use.

- Limited lifespan: not suitable for quality monitoring, except for parts placed inside a vehicle in the automotive industry. To remain legible, the label must not be altered over time.

- Less versatile: the label applicator is less reliable than a dot peen or laser marker, and is not suitable for all parts.

- Limited adhesion: Label sticks poorly to oily or rough surfaces.

Inkjet marking

Inkjet marking consists of using an inkjet print head to directly mark the part.

Less efficient and reliable than other identification solutions, this marking is the least used in the industrial field.

It is rather recommended for the marking of cardboard and food packaging.

The benefits of inkjet marking for DPM:

- High performance: inks adhere to a very wide range of materials.

- Efficient and versatile: an inkjet direct part marking machine marks soft or hard materials.

- High marking rate: the ink is quickly applied to the part to be marked.

- Marking on the fly: possibility to mark on moving parts.

- Durable: Better preservation than labeling.

The limits of inkjet marking for direct part marking:

- High cost: the cost of operation and consumables (ink, solvents) is quite high.

- Maintenance: this part marking system requires very frequent maintenance and servicing.

- Low resolution: compared with laser marking.

- Non-permanent marking: will fade over time.

The traditional marking by stamp

Stamp marking is a simple, manual part marking system. A metal tool is used to stamp a character (letters, numbers, etc.) onto metal, plastic or cardboard parts. It is also possible to find lever-operated stamping machines which make marking easier.

Its speed of execution, depth of marking and low cost are undeniable advantages. However, the wear and tear of the dies is more important and this manual identification solution excludes any notion of uniformity and compliance with marking standards.

N.B.: There are some automatic stamp machines that allow incremental marking, but their complexity and low output do not make them an ideal choice for companies.

The benefits of stamp marking

- Simple and effective: place the die and hit it with a hammer to mark the piece.

- Unique and deep marking: the die and its symbol mark even hard metals.

- Speed: marking a short sequence of characters is fast, especially as there are templates for dies.

- Low cost: the simplicity of the direct part marking machine and the absence of electronics make it a very affordable solution.

The limits of stamp marking

- Changing dies: these can be changed frequently as the dies are damaged with each use.

- Difficult increment: there are marking wheels to be hit, but they have to be turned before each marking. And an incrementing system for medium series is mechanically complex and expensive.

- Low production rates: the manual side and the difficult incrementation do not allow high production rates.

- Operator required: Requires human intervention (limited standardization of markings) or complex machine to implement.

Electrochemical marking

Designed to mark metal parts of varying sizes and shapes, electrochemical marking consists of transferring a pattern on a stencil onto a given part. Depending on the stencil, the part identification is more or less rapid.

In practice, the stencil is printed with a thermal printer and soaked in an electrolyte before being placed on the part. The hand-held marking head, connected to a generator, is then applied to the stencil in a back-and-forth motion, delivering a low current. This current, in combination with the stencil and the electrolyte, leaves a high-contrast black mark on the part.

The benefits of electrochemical marking

- Inexpensive: the direct part marking machine and consumables are affordable to make markings on ferrous metals.

- Does not change the material: the structure or shape of the material is not altered, as the marking is formed on the surface.

- Precise marking: ability to accurately mark 2D codes, number/text, and logos.

- Very good contrast: the marking is black and very visible on the metal.

- Fast: you only have to pass the marking head two or three times.

The limits of electrochemical marking

- Not very versatile: marking conductive metals only.

- Tedious installation: each marking requires its own printed stencil, marking head assembly, and electrolyte application.

- Low output: each marking is done by hand, and requires its own stencil.

- Complex: the electrolyte or stencil must be well positioned on the part (as it is placed by hand).

- Many consumables: stencils, liquid electrolyte, neutralizer, marking head felt, O-rings...

Marking with an engraving pen

An engraving pen is a hand-held industrial engraver device for quick marking of parts of various sizes.

Depending on the market, this direct part marking machine either digs into the material with its rotating diamond tip, or taps and deforms the surface of the workpiece (successive dot peen) with a carbide tip.

Space-saving and geared more towards companies customizing objects, this marking is used in industry to mark tools or equipment.

The engraving pen is available in pneumatic or electric versions. It is a simple, low-cost machine.

The benefits of marking with an engraving pen:

- Affordable: the marking system is simple, making it affordable.

- Easy to use: just plug in and switch on the engraving pen to start marking.

- Fast: to mark and write small letters.

- Portable: its small size and tapered shape make it easy to carry in a toolbox.

The limits of marking with an engraving pen:

- No standard: because marking is done by hand, it is impossible to follow industrial marking standards.

- Low production: the direct part marking machine is not suitable for medium and large production runs, since engraving is done by hand.

- Tip wear: the tip should be changed periodically, as it wears out with each use.

|

Get our DPM methods |

|---|