Since men discovered the ability to shape metal years ago, we have been marking it, be it for artistry, personalisation or traceability.

Metal is complex: conductive, reactive, composed of chemicals, alloys... When you are looking for a rotary or laser marking machine for metal, the best solution will depend on the type of metal you will be engraving:

- Stainless steel aluminium

- Anodised aluminium

- Hardened metals

- Steel alloy

- Titanium and titanium alloys

- Carbides

- Brass

- Copper

- Precious metals

- Coated metals

Why mark metal?

Metal engraving is used for the marking of text, logos, pictures, numbers, 2D codes, the list is endless. Industries marking metal are various, from jewellery to medical, automotive, aeronautics, and energy, to name a few.

Our laser marking and engraving is done without contact, and does not require any pre-treatment or post-treatment. The result is a permanent, resistant, and high contrast marking with a very high definition finish, and of course without damaging the metal.

Rotary engraving cuts away the metal using an engraving cutter similar to a drill. This allows for both engraving and cutting (on some metals) and is used extensively across all industries from engraving jewellery to cutting control panels.

Direct part marking by dot peen or scribing is performed thanks to a tungsten carbide stylus which comes into contact with the surface and deforms the material in hollow thanks to a succession of impacts which form the final marking.

Gravotech has extensive experience in metal marking and brings its expertise to help you find the best metal engraving solution that will fit your needs. There are many types of metals and we have a machine solution for each of them.

Discover Gravotech's metal engravers

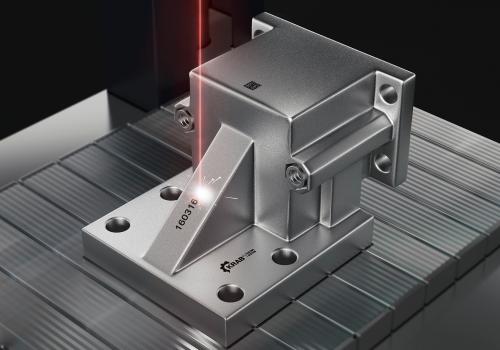

Our complete range of integrated lasers and laser stations will enable you to carry out marking on all type of metal parts, for a permanent result, with excellent quality and contrast for full identification and traceability.

Medium fully automated laser marking station.

LW2

Small laser engraver for all kind of engravings.

WELASE

Integrated laser system to mark and engrave on all metals.

FIBER laser

Large laser engraver and cutter that can do everything.

LS900

Integrated laser system for high quality marking on plastics and metals.

HYBRID laser

Medium CO2 or Fiber laser engraving and cutting machine for signage and small series.

LS100 EX

Our range of rotary machines are able to process light diamond engraving, neat deep engraving, light milling and drilling. Gravotech’s Dot peen and Scribing solutions offer very fast non-contrasted deep marking obtained by making close impacts on the surface of several metal types.

The fastest pneumatic dot peen marking machine.

XF510p

The most precise and consistent electromagnetic dot peen marking machine.

XF510M

The quiet metal scribing marking machine.

XF510r

Medium CNC engraving machine for flat and cylinder engraving on metal and plastic.

IS400 – IS400 Volume

Small and custom engraving machine for all purposes, from perfume bottle to small industrial signage.

M20

Standalone dot peen marking station.

IMPACT

Large and extra large format CNC engraving machines.

ISx000

Small CNC engraving machine for label and small part traceability system.

IS200

Lasertrace ™ facilitates the traceability and identification of all types of metal parts.

Metal laser engraving

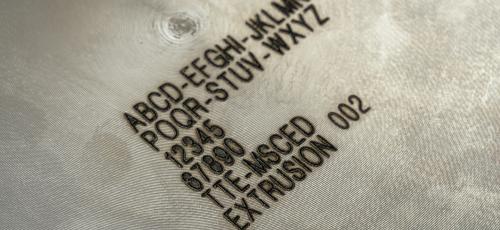

Laser etching can be used on a broad range of materials. Laser engraving occurs when the heat of the beam melts only the surface of the material and does not fully penetrate the material. The high power of the laser uses high heat to melt only the surface of the material. Oxides sometimes form in engraved areas, making the marks clearer and more visible. the laser modifies its reflectivity and improves the contrast. It removes very little material. It can be carried out on raw, anodized or plated metal surfaces. Light engraving of metals + oxides. Removes less than .001” of material. High-speed marking Works on all metals

When marked components require reworking or additional painting and the material is rough, laser engraving needs to be applied deeper into the material.

The laser creates high heat during the engraving process, which causes the material to vaporise. This creates a cavity in the surface that is noticeable to the eye and touch. It is recommended when the laser marking suffers post-process stress (such as sandblasting for die-castings).

Fast fusion and vaporisation of the material. Varying the depth is achieved by the number of passes. Only works with filled font/shapes.

Annealing

Annealing heats the material locally to just below its melting point. This generates oxide layers on the surface of the workpiece which are associated with metallic annealing colours. It is also the preferred method whenever a precision fit is required or there is a need to avoid material bulging.

You can only anneal metals that change colour when under the influence of heat and oxygen, i.e. steels and titanium, but not aluminium or non-ferrous metals. The oxide layer is black most of the time, but it can also have other annealing colours. The colour depends on the temperature of the heated layers. The material surface remains even during annealing because nothing is removed from it. The colour change is achieved through localised material heating only. The heat usually penetrates .02 to .03 mm deep in the metal surface.

Black marking

Black marking is a marking process that produces very high-contrast, dark markings. This structured surface reduces the amount of light that is reflected, and the result is a deep, matt blackening of the marking, which appears the same when viewed from any angle. This makes the marking non-abrasive. Black markings are ideal for rust-free stainless steels, titanium, copper and brass.

Metal engraving with a rotary machine

With metal engraving machines, we drag a diamond tool on the surface of the material to obtain a light and very aesthetic marking. There is no chip created and the material weight loss is insignificant, which is important particularly in jewellery.

This marking process can be used even for very hard alloys such as steel, stainless steel or iron and of course also with softer metals. It is ideal for signage (tags) and personalisation. The groove created in the part can also be filled with lacquer or wax, to obtain a high contrast or colour.

See our CNC metal engraving machine.

With CNC metal engraving machines the material is removed using cutting tools, «engraving cutters» of various sizes and shapes.

CNC is used for cutting out shapes in metal such as for control panels or for milling out 3D shapes such as the creation of hot stamps, mould insert or soft metal manufacturing. This technology can also be used to obtain text, numbers or logos deeply engraved in the part, whether it is for identification (direct part marking) of personalisation purposes.

This marking process provides excellent non-contrasted results both for cutting or milling, and even our small engravers can do the job in soft metal such as aluminium or brass.

Our pneumatic dot peen marking machines are the best for marking applications requiring a very short cycle time to meet the speed requirements of industrial sectors.

The electromagnetic marking machines are more suitable for applications needing great precision and consistency. It is particularly efficient for DataMatrix code marking. The electromagnetic dot peen marking machine is a high-precision marking solution to meet traceability and identification requirements.

Our dot peen metal marking machines are economical with clear marking, marking twice as fast as other dot peen machines.

Silent with aesthetic and amazing results, scribing machines are used in all industrial operations, subject to noise level limitations: large metal components (beams, rails, chassis and exhaust pipes etc.), VIN marking (Vehicle Identification Numbers) on cars, motorbikes and heavyweight vehicles, etc.

This is the best marking/speed depth ratio solution. It provides high quality marking. It was developed for heavy industrial applications, our systems are durable and require very little maintenance.

Personalisation

Make it unique, create emotions

You are a luxury brand or an international brand and you would like to develop an exclusive in store customer experience for your clients, on your e-commerce site or during an event?

Gravotech offers tailored solutions that will meet your needs. A dedicated project manager will guide you throughout the collaboration: discussing requirements, running samples on your products, selecting the best-suited personalisation technology, solution deployment and user training.